Custom Automation Solutions For Manufacturing Facilities

Food Processing, Medical Device, Industrial Facilities & More

30+ Successful implementations across north america

We Help Manufacturing Leaders:

ROI within 12 months

Increase production throughput

Eliminate quality inconsistencies

enable true 24/7 production

Improve operator safety

Trusted By Industry Leaders:

Watch: How We Transform Manufacturing Operations

Located: Ottawa, Ontario, Canada

Serving: All of Canada/US

Get Your Free Automation Assessment

No obligation • 30-minute call • Custom recommendations

"We commissioned Mechatronic D.S to design and build a system to automate a complex multi-step production process.

The output was a multi-arm manufacturing robot/press system which we have been running 100+ hours per week with great success. I highly recommend this talented team"

- Dave Lajeunesse, VP Operations, Carbitex

“Collaborating with MechDS for our project engineering services has been a highly beneficial experience.

Initially, we were unsure if we should hire an external consultant or handle everything internally, but we are thrilled with our decision to partner with MechDS.

Their ability to articulate our project vision to all stakeholders was impressive and set a solid foundation for success.

Leveraging their food manufacturing, engineering, and risk mitigation expertise, they provided innovative solutions that saved us hundreds of thousands of dollars.

I highly recommend MechDS to any organization seeking top-tier project engineering services.“

- Peter Todd, Director of Supply Chain, Customer Service & Projects

"Our products need to be interchangeable. Mechatronic DS provided a suite of engineering services that included product design, assembly fixtures and inspection jigs. They were always professional and a joy to work with"

- Steve White, Engineering Manager, Sciemetric

What Others Are Saying

What Others Are Saying

"Partnering with MechDS was a great decision for Activar. We faced a unique challenge with our robotic press tending system, where parts stuck together and no off-the-shelf gripper was suitable.

MechDS designed, built, and installed a clever and robust custom gripper and robotic cell. Initially, I was concerned about receiving support from a company geographically far, but their team was fast and effective.

Their innovative solutions and outstanding service have made a significant positive impact on our operations. Ultimately helping Activar achieve in increasing productivity output by 20-30% and reducing scrap rates by 12% from our manual loading process.

I highly recommend MechDS for their professionalism, on time delivery, and great attention to detail."

- Dustin Morris, Manufacturing Engineer, Activar Construction Projects Group Inc.

"Automating industrial cooking can be intimidating. Mechatronic DS removed the risk from this process and helped our company realize a safe, reliable, and quality solution that will pay dividends for years to come"

- Worku Mindaye, CEO, Shega Foods

"I would not hesitate to recommend Mechatronic Design Solutions for your custom automation needs. We received great value on our project, and timely follow up support when needed"

- Philip Locker, Chief Operating Manager, Competition Composites

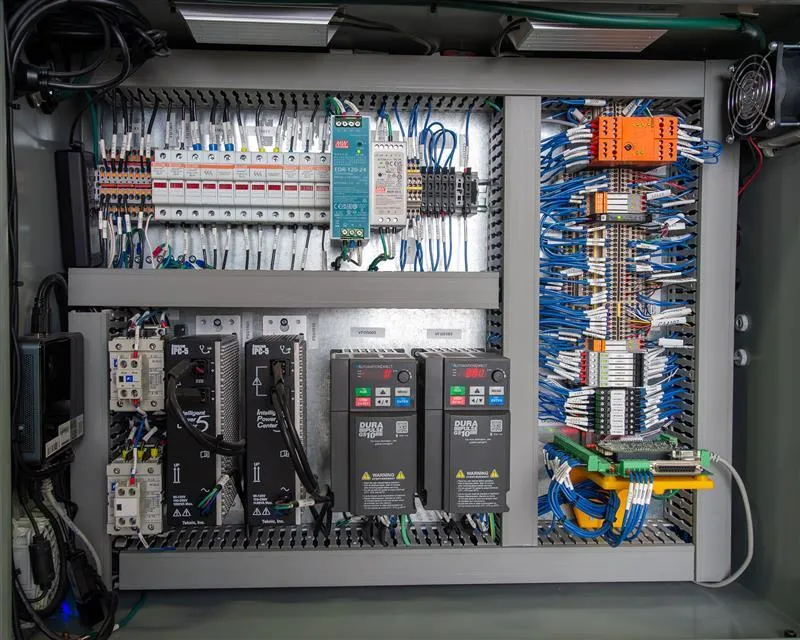

"MechDS designed, built, and installed a fully automated robotic machine tending system.

Their expertise in robotics, electrical, and mechanical engineering resulted in a solution that met our unique requirements. Our work in testing, inspection, and certification for mining required a reliable and durable solution, while being precise and traceable.

The robotic cell has been running tens of thousands of batches per year. We highly recommend MechDS for their innovative industrial automation solutions."

- Andrew Pickering, Global Vice President Business Development, SGS

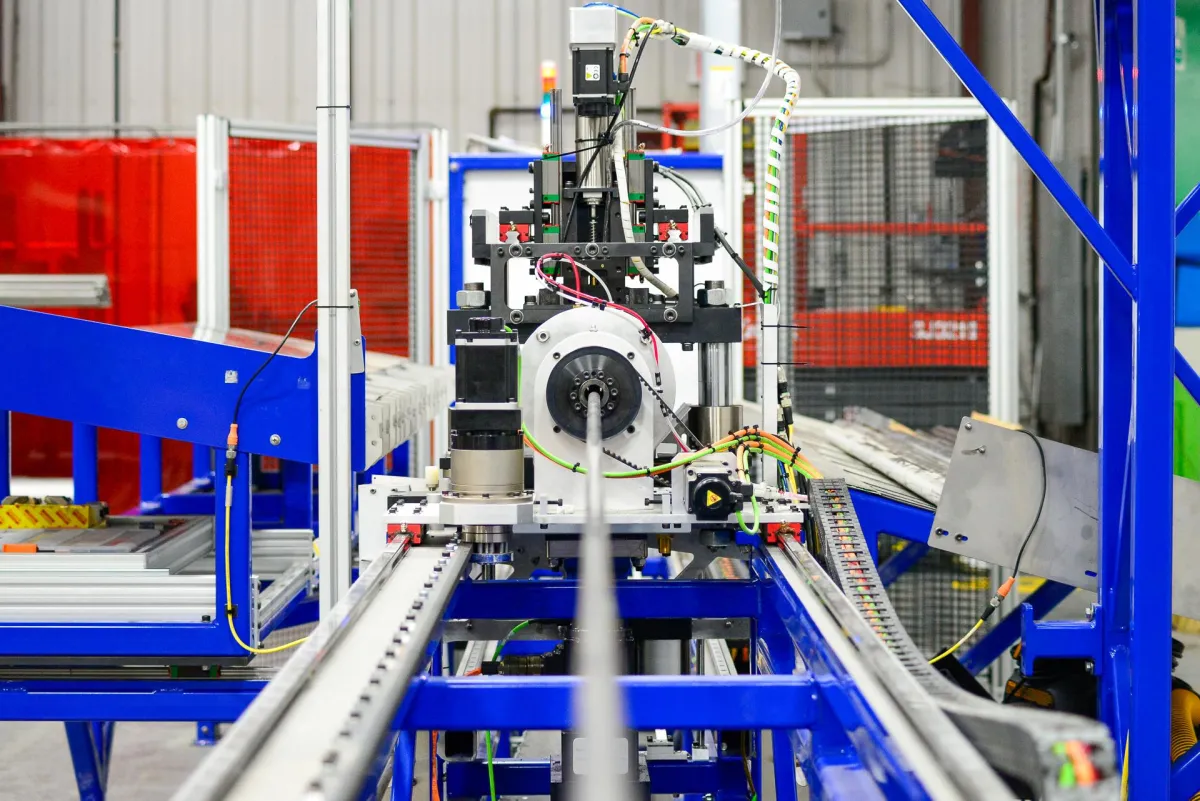

"MechDS designed, built, and installed a fully automated punching and assembly system for our manufacturing business.

Their expertise in PLC, electrical, and mechanical engineering resulted in a solution that met our unique requirements.

No machine on the market met our needs to manufacture hundreds of different product configurations with a wide variability in product size.

The machine has been running for years producing hundreds of thousands of parts. We highly recommend MechDS for their innovative industrial automation solutions."

- Stephen Luketich, Operations Manager Americas, Condair

"Mech DS is a long-term strategic partner that has provided our company with reliable engineering support. Their speed of project completion has been critical in our innovation cycles"

- Josh Ogden, CEO, AVSS

Project Examples & Outcomes

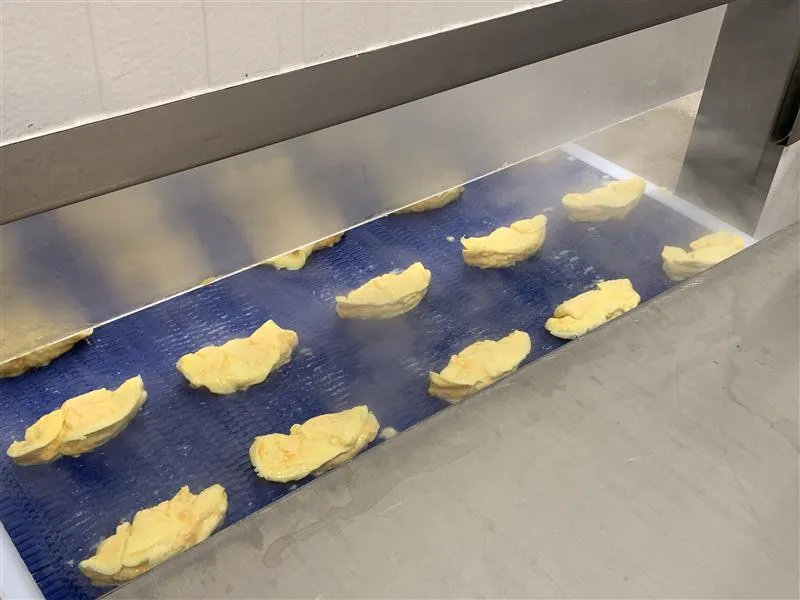

High-Accuracy Robotic Dispenser System

CHALLENGE

Food manufacturer struggling with dispensing difficult-to-handle foods such as batter, egg, crepe mix, injera, thin dispensing, pie filling, and custom icing.

SOLUTION

MechDS implemented a High-Accuracy Robotic Dispenser System designed specifically for demanding food processing applications.

RESULTS

Dispensing accuracy of ±3 ml (variable based on application)

Production rate of up to 30 products per minute

Payback period within 8 months

Versatile application for crepes, sauces, icing and florets, pie fillings, and muffins

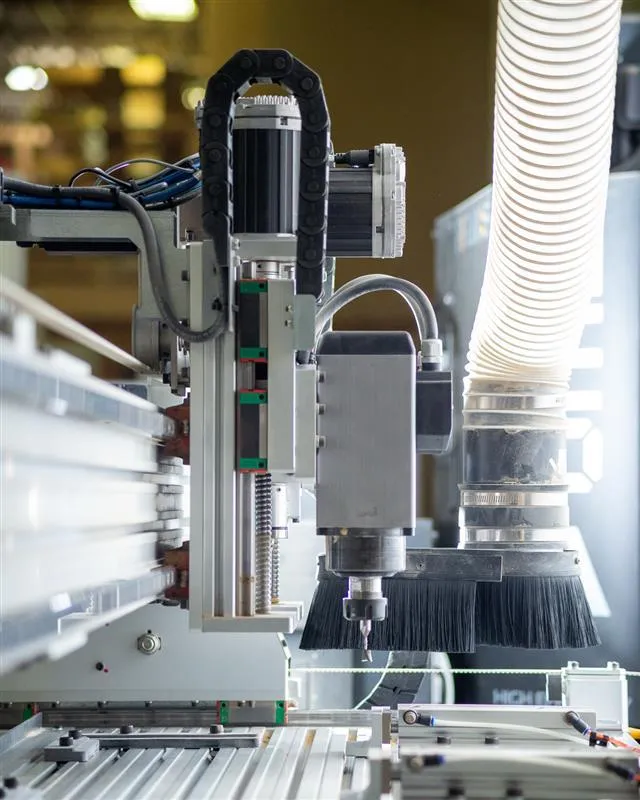

Automated Door Jamb CNC

CHALLENGE

Manufacturers needed to automate door jamb production with consistent quality while reducing labor requirements.

SOLUTION

MechDS developed a specialized Door Jamb CNC with automated loading and unloading magazines for wood, plastic, and composite materials.

RESULTS

Production rate of 80-100 units per hour

Payback achieved in 6 to 12 months

2-hour autonomy between loading operations

Handles stock sizes from 1-10 ft length × 2-12 in width × 0.5-2 in thickness

Automated Packaging Denester

CHALLENGE

Food manufacturers needed efficient separation of packaging materials like punnets, trays, cartons, and clamshells without damaging delicate containers.

SOLUTION

MechDS created a Vacuum Denester system utilizing innovative vacuum gripping technology for gentle handling of diverse packaging types.

RESULTS

Denesting speed of 30 containers per minute (scalable to 60 cpm in two-head configuration)

Payback within 8 months

Compatible with numerous packaging types: punnet, tray, clamshell, carton, cardstock, foam, and plastic

Complete with touchscreen control, remote access, and real-time diagnostics

Lettuce Packaging Line

CHALLENGE

Indoor agriculture, hydroponic, and agroponic farms struggled with labor shortages and finding suitable quality control and packaging systems.

SOLUTION

MechDS developed a custom Lettuce Packaging Line with hygienic washdown-safe construction specifically for spring mix, kale, romaine, oak lettuce, and spinach.

RESULTS

Throughput of 20-60 packages per minute

Compatible with multiple packaging options: clamshells, punnets, cartons, and bags

Fully washdown-capable with stainless steel and food-safe plastic construction (IP68 rated)

Equipped with gentle vibratory sifting and automated package handling

Automation Solutions

For Manufacturing Facilities

Food Processing, Medical Device,

Industrial Facilities & More

30+ Successful implementations

across north america

We Help Manufacturing Leaders:

ROI within 12 months

Increase production throughput

Eliminate quality inconsistencies

enable true 24/7 production

Improve operator safety

Trusted By Industry Leaders:

"MechDS designed, built, and installed a fully automated robotic machine tending system.

Their expertise in robotics, electrical, and mechanical engineering resulted in a solution that met our unique requirements. Our work in testing, inspection, and certification for mining required a reliable and durable solution, while being precise and traceable.

The robotic cell has been running tens of thousands of batches per year. We highly recommend MechDS for their innovative industrial automation solutions."

- Andrew Pickering, Global Vice President Business Development, SGS

Get Your Free Automation Assessment

No obligation • 30-minute call • Custom recommendations

what others are saying

"Partnering with MechDS was a great decision for Activar. We faced a unique challenge with our robotic press tending system, where parts stuck together and no off-the-shelf gripper was suitable.

MechDS designed, built, and installed a clever and robust custom gripper and robotic cell. Initially, I was concerned about receiving support from a company geographically far, but their team was fast and effective.

Their innovative solutions and outstanding service have made a significant positive impact on our operations. Ultimately helping Activar achieve in increasing productivity output by 20-30% and reducing scrap rates by 12% from our manual loading process.

I highly recommend MechDS for their professionalism, on time delivery, and great attention to detail."

- Dustin Morris, Manufacturing Engineer, Activar Construction Projects Group Inc.

"MechDS designed, built, and installed a fully automated punching and assembly system for our manufacturing business.

Their expertise in PLC, electrical, and mechanical engineering resulted in a solution that met our unique requirements.

No machine on the market met our needs to manufacture hundreds of different product configurations with a wide variability in product size.

The machine has been running for years producing hundreds of thousands of parts. We highly recommend MechDS for their innovative industrial automation solutions."

- Stephen Luketich, Operations Manager Americas, Condair

“Collaborating with MechDS for our project engineering services has been a highly beneficial experience.

Initially, we were unsure if we should hire an external consultant or handle everything internally, but we are thrilled with our decision to partner with MechDS.

Their ability to articulate our project vision to all stakeholders was impressive and set a solid foundation for success.

Leveraging their food manufacturing, engineering, and risk mitigation expertise, they provided innovative solutions that saved us hundreds of thousands of dollars.

I highly recommend MechDS to any organization seeking top-tier project engineering services.“

- Peter Todd, Director of Supply Chain, Customer Service & Projects

Project Examples & Outcomes

High-Accuracy Robotic Dispenser System

CHALLENGE

Food manufacturer struggling with dispensing difficult-to-handle foods such as batter, egg, crepe mix, injera, thin dispensing, pie filling, and custom icing.

SOLUTION

MechDS implemented a High-Accuracy Robotic Dispenser System designed specifically for demanding food processing applications.

RESULTS

Dispensing accuracy of ±3 ml (variable based on application)

Production rate of up to 30 products per minute

Payback period within 8 months

Versatile application for crepes, sauces, icing and florets, pie fillings, and muffins

Automating industrial cooking can be intimidating. Mechatronic DS removed the risk from this process and helped our company realize a safe, reliable, and quality solution that will pay dividends for years to come

- Worku Mindaye, CEO, Shega Foods

Automated Door Jamb CNC

CHALLENGE

Manufacturers needed to automate door jamb production with consistent quality while reducing labor requirements.

SOLUTION

MechDS developed a specialized Door Jamb CNC with automated loading and unloading magazines for wood, plastic, and composite materials.

RESULTS

Production rate of 80-100 units per hour

Payback achieved in 6 to 12 months

2-hour autonomy between loading operations

Handles stock sizes from 1-10 ft length × 2-12 in width × 0.5-2 in thickness

"We commissioned Mechatronic D.S to design and build a system to automate a complex multi-step production process.

The output was a multi-arm manufacturing robot/press system which we have been running 100+ hours per week with great success. I highly recommend this talented team"

- Dave Lajeunesse, VP Operations, Carbitex

Automated Packaging Denester

CHALLENGE

Food manufacturers needed efficient separation of packaging materials like punnets, trays, cartons, and clamshells without damaging delicate containers.

SOLUTION

MechDS created a Vacuum Denester system utilizing innovative vacuum gripping technology for gentle handling of diverse packaging types.

RESULTS

Denesting speed of 30 containers per minute (scalable to 60 cpm in two-head configuration)

Payback within 8 months

Compatible with numerous packaging types: punnet, tray, clamshell, carton, cardstock, foam, and plastic

Complete with touchscreen control, remote access, and real-time diagnostics

Our products need to be interchangeable. Mechatronic DS provided a suite of engineering services that included product design, assembly fixtures and inspection jigs. They were always professional and a joy to work with

- Steve White, Engineering Manager, Sciemetric

Lettuce Packaging Line

CHALLENGE

Indoor agriculture, hydroponic, and agroponic farms struggled with labor shortages and finding suitable quality control and packaging systems.

SOLUTION

MechDS developed a custom Lettuce Packaging Line with hygienic washdown-safe construction specifically for spring mix, kale, romaine, oak lettuce, and spinach.

RESULTS

Throughput of 20-60 packages per minute

Compatible with multiple packaging options: clamshells, punnets, cartons, and bags

Fully washdown-capable with stainless steel and food-safe plastic construction (IP68 rated)

Equipped with gentle vibratory sifting and automated package handling

Mech DS is a long-term strategic partner that has provided our company with reliable engineering support. Their speed of project completion has been critical in our innovation cycles

- Josh Ogden, CEO, AVSS

An Important Message for manufacturing Leaders

By Aaron Robert

Published: Mar, 3rd 2025 at 11:37am EST

Whether you're struggling with manual processes or looking to optimize your existing automation...

Every manufacturing leader faces a common challenge:

Maximizing operational efficiency.

For some, it's the limitations of manual labor.

For others, it's automated systems that can't keep up with today's demands.

As a VP of operations, plant manager, or business owner with P&L responsibility, you know that every inefficiency directly impacts your bottom line.

That's why manufacturers across North America are turning to Mechatronic Design Solutions.

We've helped over 30 manufacturing facilities across North America.

From those just starting their automation journey, to those upgrading their existing systems...

Achieve transformation that delivers ROI within 12 months.

You know the challenges

Whether it's production lines still waiting for automation, or existing systems that are not delivering the ROI you expected.

Your targets keep rising.

But finding the right automation solution (or optimizing what you already have)

Gets more complex every day.

When you're responsible for operational excellence...

Every breakdown...

Every inefficiency...

Every missed deadline...

Cuts into your performance.

Your competition is constantly modernizing.

And you can't help but wonder...

Are you maximizing your automation potential?

Let's be honest—Manufacturing has changed dramatically.

Whether you're dealing with labour retention issues, or struggling with under performing automated systems.

The challenges are mounting:

Rising operational costs...

Increasing quality demands...

Growing competitive pressure...

Complex integration requirements...

And escalating safety standards.

Every inefficient process in your facility. Whether manual or poorly automated.

Is not just a bottleneck...

It's a liability that's affecting your P&L performance

Your competitors understand this.

That's why they're investing in smart automation solutions.

Gaining advantages in consistency...

Scalability...

And cost...

...That'll be very hard to overcome if you wait too long to optimize your operations.

This is where Mechatronic Design Solutions comes in

Whether you're taking your first steps into automation...

Or looking to enhance your existing systems.

We deliver solutions that transform your operation.

From complete robotic turnkey work cells, to strategic automation projects.

We customize our approach to your specific needs.

Mech DS specializes in solving the challenging automation problems that other providers avoid.

This includes complex material handling that demands precision...

High speed production requiring perfect consistency...

Difficult to handle food packaging operations...

And intricate manual food processing such as folding, forming and shaping.

Our solutions maximize throughput,

enhance safety, and enable 24/7 production

Our solutions maximize throughput, enhance safety, and enable 24/7 production

Hi, I'm Aaron Robert.

Director of Business Development at Mechatronic Design Solutions.

As someone who works directly with VPs, plant managers, and business owners...

I understand the pressures you face to deliver results.

Over the past four years, my team has deployed more than 30 custom automation solutions across North America.

From food processing plants...

To medical device companies...

And light industrial fabricators...

We've worked with businesses at every stage of automation maturity. Ranging from millions to billions in revenue.

As an engineering firm with a certificate of authorization, professional engineers, and certified machine safety experts on staff...

We bring unmatched expertise to every project, whether it's your first automation implementation, or an upgrade to an existing system.

Now, you might be wondering...

How do we know this will actually work For you?

It's a fair question.

Especially if you've had disappointing experiences with automation providers before.

Many automation projects fail because they skip crucial steps.

That's why we've developed a systematic six step process that eliminates risk and ensures success regardless of your current automation maturity.

Step 1: preparation and planning

We start where others don't.

With a deep understanding of your operation.

For plant managers and operational VPs, this means...

We map your entire production flow

Identify efficiency opportunities

Analyze existing systems

Document your environmental requirements

And review your preferred components and suppliers

"But what if we don't have everything figured out?", you might be wondering.

Whether you're planning your first automation project, or upgrading an existing system...

Our team of experts will guide you through opportunity identification, and help you prioritize automation targets.

We'll identify quick win opportunities...

Develop comprehensive specifications...

And create integration strategies for existing systems.

As well, you'll receive a rough order of magnitude quote early in the process so that there are no budget surprises.

Step 2: Evaluation

Next comes evaluation...

How will you know we're the right partner?

As a leader with P&L responsibility, you need confidence in your automation partner.

Our unique size of 30 technical experts means we're perfectly balanced.

We're large enough for redundancy in every technical role. And small enough to be agile and responsive...

With deep expertise in regulated industries, and no bureaucratic delays.

During step 2 we'll provide you with an evaluation matrix that will compare...

Technical capabilities for new and upgrade projects

Industry specific experience

Support infrastructure

Implementation methodology

Integration experience

Step 3: Design

The third step is design.

The main question here is, "What if our needs change during the project?"

Our process is built for flexibility.

Weekly design reviews keep you in control

Early prototyping eliminates risk

3D modelling shows exactly what you're getting

Clear documentation will be provided for all interfaces

And an action registry will track every decision

You'll never be left wondering about progress or timeline.

Step 4: Factory Acceptance

The fourth step is factory acceptance.

So how will you know the system will actually work?

For operation leaders who can't afford disruption, this is where our process really shines.

Before anything is shipped...

Extended testing is conducted with your actual products

Performance metrics are verified and documented

All safety systems are thoroughly tested

Operator training will begin in a controlled environment

And the complete system is validated.

Everything is backed by a contractual performance guarantee.

Step 5: Installation

The fifth step is installation.

A common question here is, "What about disruption to our operations?"

We do everything in our power to minimize impact to your existing operations:

Detailed pre-installation planning

Strategic scheduling around your production needs

Professional installation teams

Comprehensive training for all shifts

Full documentation and maintenance guides

And performance verification under real conditions

Step 6: Ongoing Support

The sixth and final step is ongoing support.

We're sometimes asked:

"How will you support us remotely?"

Distance is no barrier...

24/7 remote monitoring diagnostics can be provided

We'll include a VPN access for immediate troubleshooting

A local technical resource for rapid response

Comprehensive spare parts programs (reduced downtime)

We'll schedule regular preventative maintenance visits

And provide continuous optimization support

And if you don't have technical staff?

Our systems are designed for ease of use. There will be minimal operator interventions required.

Simple and intuitive controls...

Clear maintenance procedures...

Ongoing training and support...

And remote assistance where needed.

Imagine where your facility could

be in the next 12 months

Imagine where your facility could be in the next 12 months

Month 1 - A complete automation strategy developed

Month 3 - Custom solution designed and validated

Month 6 - The new system is installed or existing system optimized.

Month 12 - ROI targets achieved

The manufacturing leaders who work with us consistently achieve:

Reliable 24/7 production capability

Optimized operational costs

Improved product quality and consistency

Enhanced workplace safety

And a greater competitive edge advantage

we don't just promise performance,

We guarantee it in writing

we don't just

promise performance,

We guarantee it in writing

Whether we're implementing new automation or existing systems are being enhanced...

Your success is a contractual commitment.

The performance metrics are guaranteed in writing

The acceptance criteria is clearly defined up front

Testing is conducted with your actual products

Integration success is verified

You verify the performance and confirm before final acceptance

And we're accountable for meeting every specification

If we don't deliver exactly what we promise...

We'll make it right.

The math is simple

Every day of inefficient operation...

Whether from manual processes or under-performing automation...

Costs you in:

Productivity, quality, and competitive advantage.

Our solutions typically deliver ROI within 12 months through:

Optimized Operational Costs.

Increased Throughput.

Increased Quality.

And Enhanced System Performance.

Take the first step...

Schedule a no obligation consultation to explore what's possible for your facility.

a reality check for manufacturing leaders

While you're reading this, your competitors are already optimizing their operations.

Every month of delay means more revenue lost to inefficiency.

It means more quality inconsistencies...

More ground loss to competitors...

And more operational stress.

These challenges compound daily.

Lost production opportunities...

Ongoing quality issues...

Preventable incidents...

Employee frustration...

And market share erosion.

These costs don't show up as a single line on your P&L...

But they're steadily eroding your competitive position.

Now here's a critical insight...

Industry analysts predict automation will account for 25 percent of manufacturing capital spending over the next five years. (source, Mckinsey)

The question is not whether your industry will optimize through automation.

It's whether you'll lead the change...

Or struggle to catch up.

Whether you're starting your automation journey or enhancing existing systems...

The time for action is now.

Don't let your competitors gain an insurmountable advantage.

Schedule a consultation to explore what's possible for your facility by clicking the button below now.

Aaron Robert

Director of Business Development

Mechatronic Design Solutions